In aluminum die-casting, hydrogen gas is a common impurity that must be removed from molten aluminum to prevent porosity and weak casting results. The process of removing this gas is called degassing, and there are several tools used for this purpose—mainly the degassing unit, shaft, and impeller.

But what are the differences between them? When should you use each one? Let’s break it down in a way that’s easy to understand.

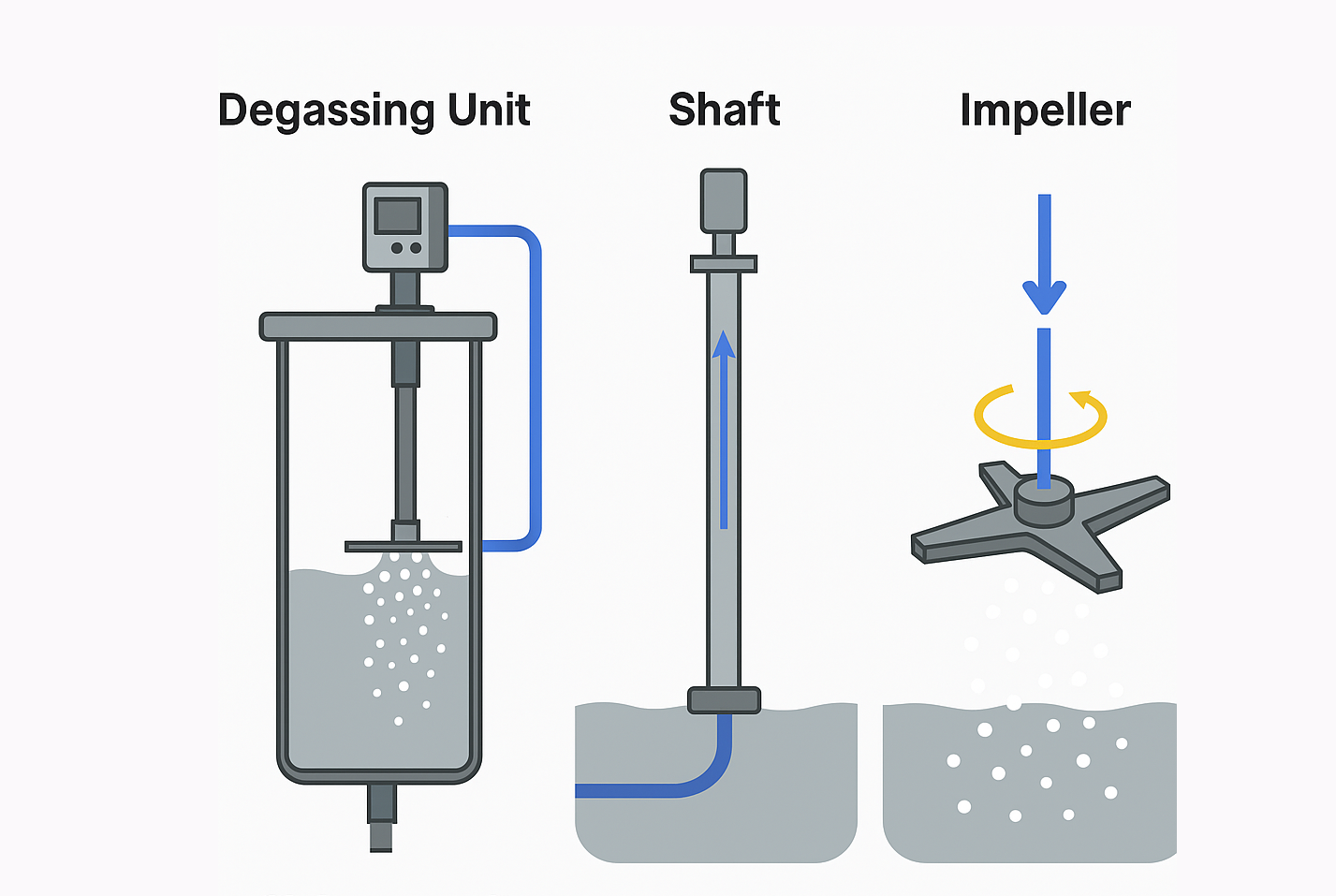

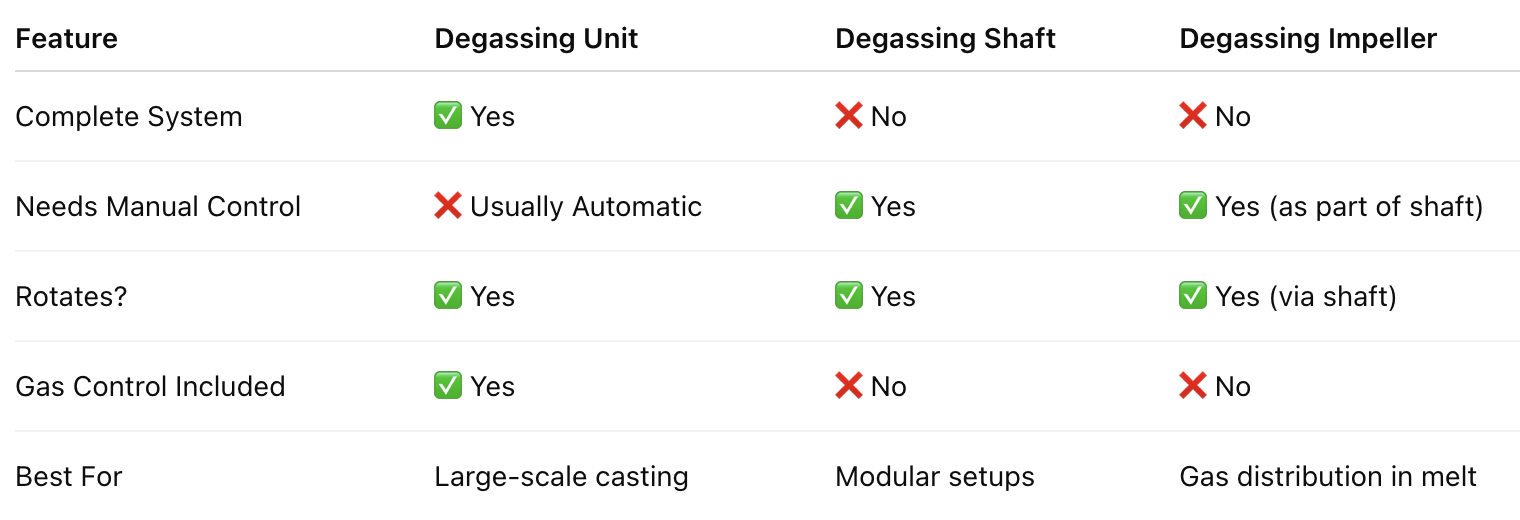

1. Degassing Unit

A degassing unit is a complete system used to purify molten aluminum by injecting an inert gas (usually nitrogen or argon). It often includes a control panel, gas injection system, rotating mechanism, and can be fully or semi-automatic.

Key Features:

- ✅ Offers precise gas flow control

- ✅ Usually comes with temperature and rotation settings

- ✅ Ensures consistent degassing quality

- ✅ Suitable for large-scale or industrial production

Use Case: Ideal for companies that produce large quantities of aluminum and want to ensure stable, repeatable results.

2. Degassing Shaft

A degassing shaft is a component that connects the motor (or operator) to the impeller. It introduces the inert gas into the molten aluminum and rotates to help distribute the gas bubbles.

Key Features:

- ✅ Durable in high-temperature environments

- ✅ Can be used manually or with a unit

- ✅ Made from non-reactive materials like graphite

Use Case: A great choice for companies that already have a gas source and rotation motor, or want a more modular setup.

3. Degassing Impeller

The impeller is the rotating part at the end of the shaft. It breaks the gas into small bubbles and ensures even distribution in the molten metal.

Key Features:

- ✅ Improves gas-to-metal contact

- ✅ Available in various designs (flat, tapered, etc.)

- ✅ Made from graphite or other resistant materials

Use Case: The impeller works together with the shaft and is crucial for the actual gas mixing process. Without it, gas distribution would be poor.

Each degassing tool plays a different role, and they often work together as a system. Whether you’re a student learning about aluminum processing or a die-casting practitioner looking to upgrade your setup, understanding the difference between a unit, shaft, and impeller is key to producing high-quality castings.

Need help choosing the right degassing equipment?

Contact PT. Wilisindomas Indahmakmur – we’re here to help with expert solutions for your aluminum die-casting needs.