Is your furnace hot outside? That’s a red flag.

Is your furnace hot outside? That’s a red flag.

In aluminum die-casting operations, furnace performance is often judged by what happens inside: metal temperature, holding stability, and casting quality. But one of the clearest warning signs of a problem is actually on the outside.

If your furnace shell is hot to the touch, it’s not just uncomfortable—it’s a serious indicator of poor insulation performance and energy loss.

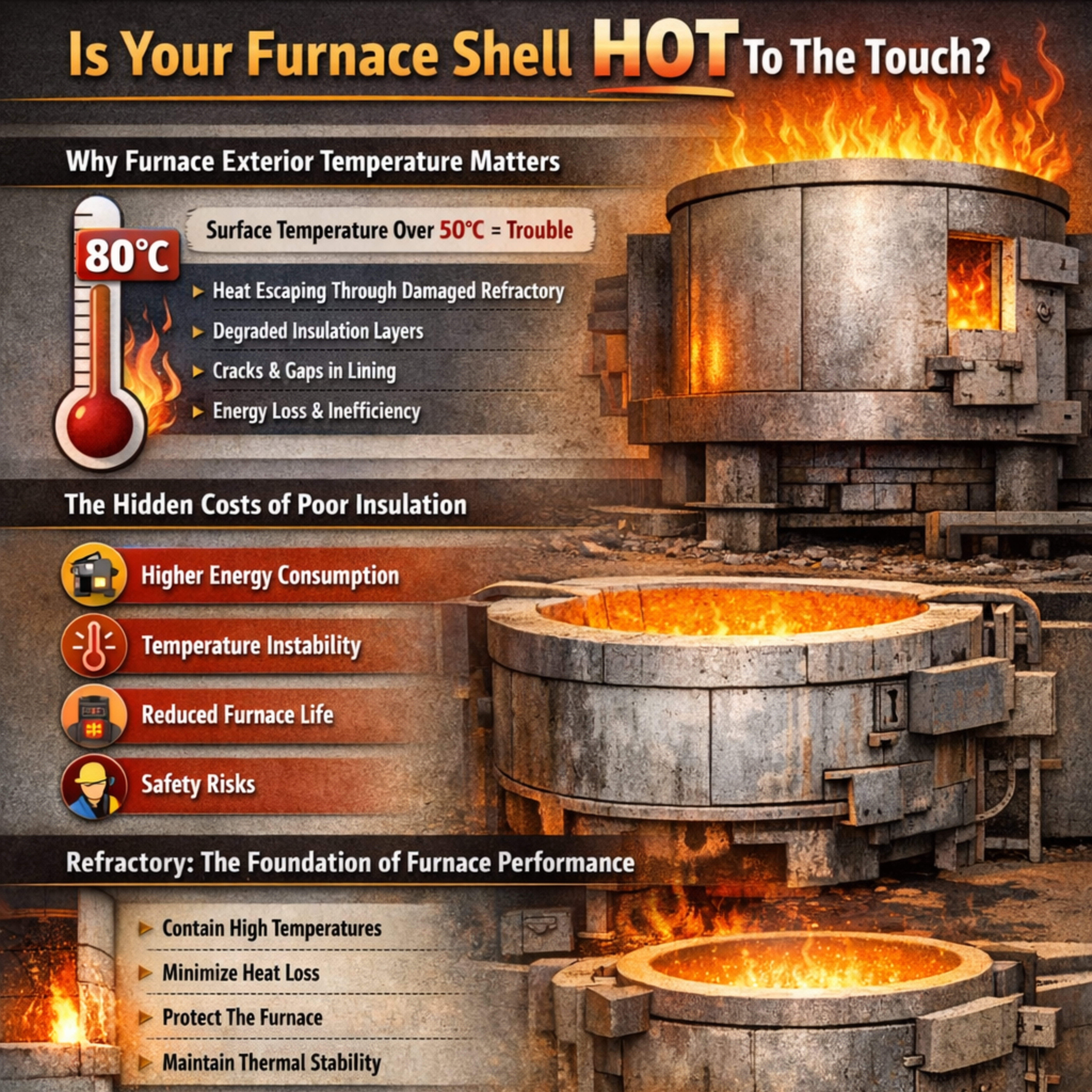

Why Furnace Exterior Temperature Matters

A properly insulated holding furnace should retain heat inside the refractory lining, not radiate it outward. When the furnace body becomes excessively hot, it usually means:

In well-designed and well-maintained furnaces, external surface temperatures should remain below 50° C. Even during continuous operation, anything higher is a red flag.

The Hidden Costs of Poor Furnace Insulation

Refractory: The Foundation of Furnace Performance

The primary thermal barrier in any holding furnace has an important role to:

Over time, refractory materials are exposed to extreme heat, molten aluminum contact, mechanical stress and chemical attack. Without proper material selection and maintenance, insulation performance inevitably degrades.

PTWI Refractory Solutions for Holding Furnaces

We supply and install refractory systems designed specifically for aluminum holding furnace applications. Our refractory solutions focus on:

In addition to refractory supply, we support furnace performance through inspection, repair, and maintenance services to restore insulation integrity and operational reliability.

When to Take Action

It’s time to contact PT Wilisindomas Indahmakmur today to learn how proven refractory insulation solutions can reduce heat loss, improve furnace efficiency, and keep external surface temperatures safely below 50°C.

Is your furnace hot outside? That’s a red flag.

Is your furnace hot outside? That’s a red flag.

In aluminum die-casting operations, furnace performance is often judged by what happens inside: metal temperature, holding stability, and casting quality. But one of the clearest warning signs of a problem is actually on the outside.

If your furnace shell is hot to the touch, it’s not just uncomfortable—it’s a serious indicator of poor insulation performance and energy loss.

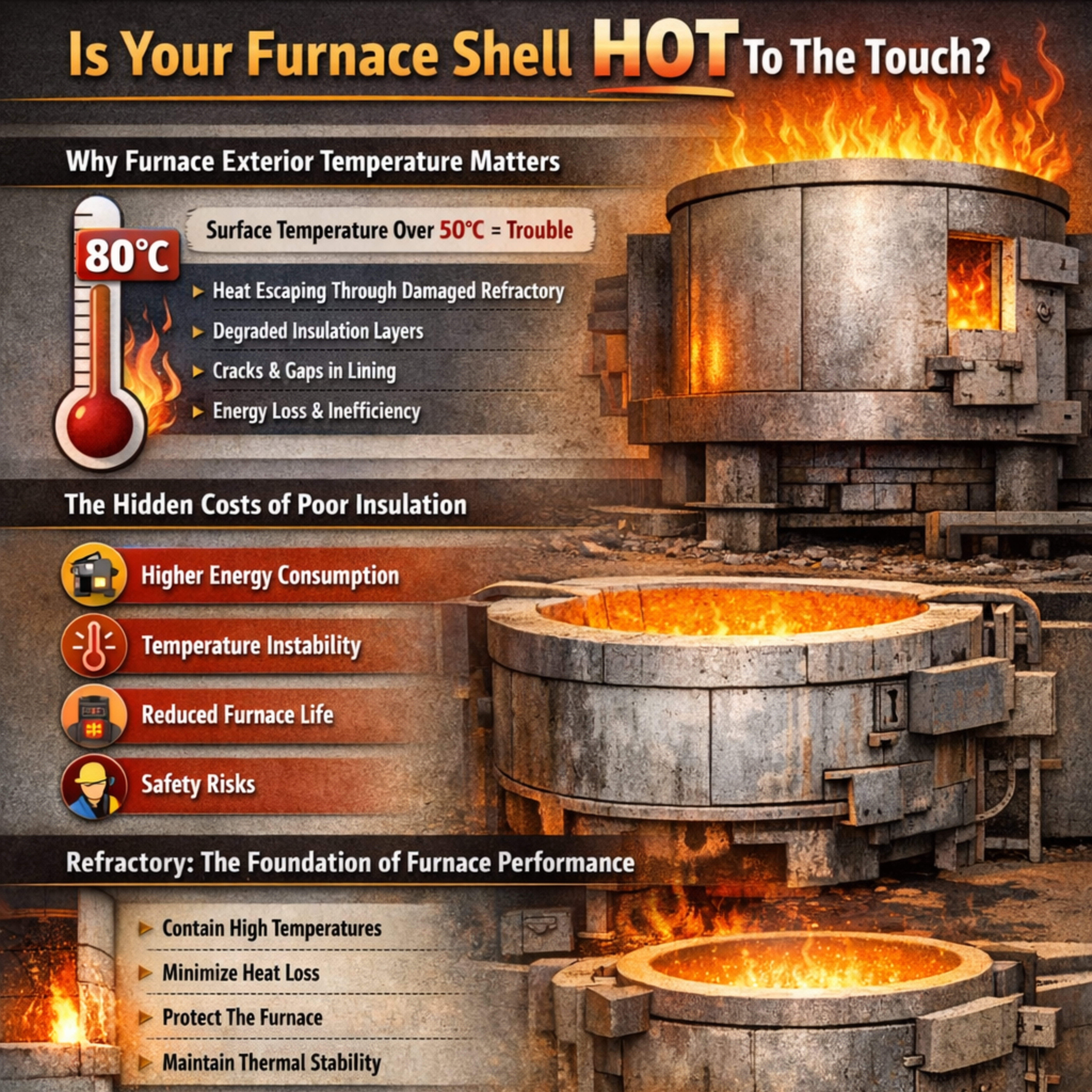

Why Furnace Exterior Temperature Matters

A properly insulated holding furnace should retain heat inside the refractory lining, not radiate it outward. When the furnace body becomes excessively hot, it usually means:

In well-designed and well-maintained furnaces, external surface temperatures should remain below 50° C. Even during continuous operation, anything higher is a red flag.

The Hidden Costs of Poor Furnace Insulation

Refractory: The Foundation of Furnace Performance

The primary thermal barrier in any holding furnace has an important role to:

Over time, refractory materials are exposed to extreme heat, molten aluminum contact, mechanical stress and chemical attack. Without proper material selection and maintenance, insulation performance inevitably degrades.

PTWI Refractory Solutions for Holding Furnaces

We supply and install refractory systems designed specifically for aluminum holding furnace applications. Our refractory solutions focus on:

In addition to refractory supply, we support furnace performance through inspection, repair, and maintenance services to restore insulation integrity and operational reliability.

When to Take Action

It’s time to contact PT Wilisindomas Indahmakmur today to learn how proven refractory insulation solutions can reduce heat loss, improve furnace efficiency, and keep external surface temperatures safely below 50°C.