Water-based die lube killing your dies? There’s a better solution!

Die life is one of the biggest cost drivers in aluminum die-casting operations. Yet many foundries continue to experience premature die cracking, heat checking, and surface damage, often without realizing that the root cause may be their die lubrication system.

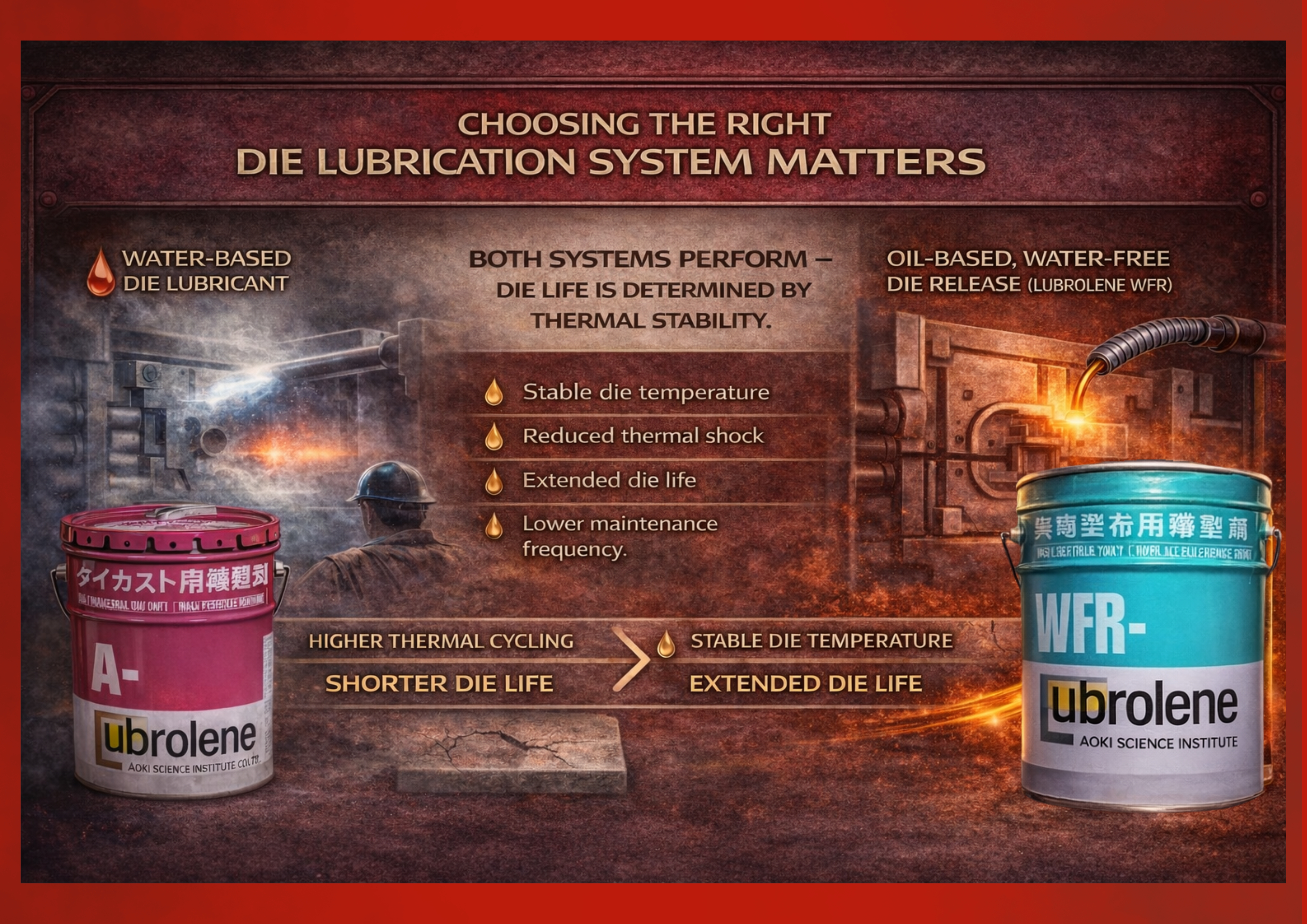

If you are relying on water-based die lubricants, the problem may not be lubrication performance alone, but thermal shock caused by water contact on hot die surfaces.

The hidden problem with water-based die lubricants.

Water-based die lubes are widely used due to their cooling effect and ease of application. However, when sprayed onto dies operating at high temperatures, water evaporates instantly, creating rapid temperature fluctuations on the die surface.

This repeated cycle of sudden cooling from water spray and rapid reheating during metal injection leads to thermal shock, which accelerates heat checking and micro-cracking, surface erosion, soldering issues and shortened die life. Over time, this instability reduces die durability and increases maintenance and replacement costs.

Why stable Die temperature matters?

Maintaining a stable die temperature is critical for:

Large temperature swings weaken die steel and promote crack propagation. Even with correct spray patterns and dilution ratios, water-based systems inherently introduce thermal instability due to the presence of water.

Oil-based, water-free release: A smarter alternative.

Oil-based, water-free Die release systems eliminate the root cause of thermal shock by removing water from the equation entirely. Instead of cooling the die surface abruptly, oil-based systems:

Lubrolene WFR as a solution.

Lubrolene WFR (Water-Free Release) is an oil-based die release system engineered specifically to stabilize die temperature and protect die surfaces under demanding die-casting conditions.

Key performance advantages include:

Because Lubrolene WFR relies on controlled lubrication rather than aggressive cooling, it supports consistent thermal balance throughout the casting cycle. By switching from water-based die lubricants to a water-free oil-based system, foundries can achieve reduced die cracking and heat checking, longer intervals between die maintenance, improved casting surface quality and a more stable and predictable production. This approach is especially beneficial for high-temperature, high-cycle aluminum die-casting operations where die life directly impacts profitability.

For expert guidance and product recommendations tailored to your operation, contact PT Wilisindomas Indahmakmur.