Porosity still a problem? Check your Degassing System!

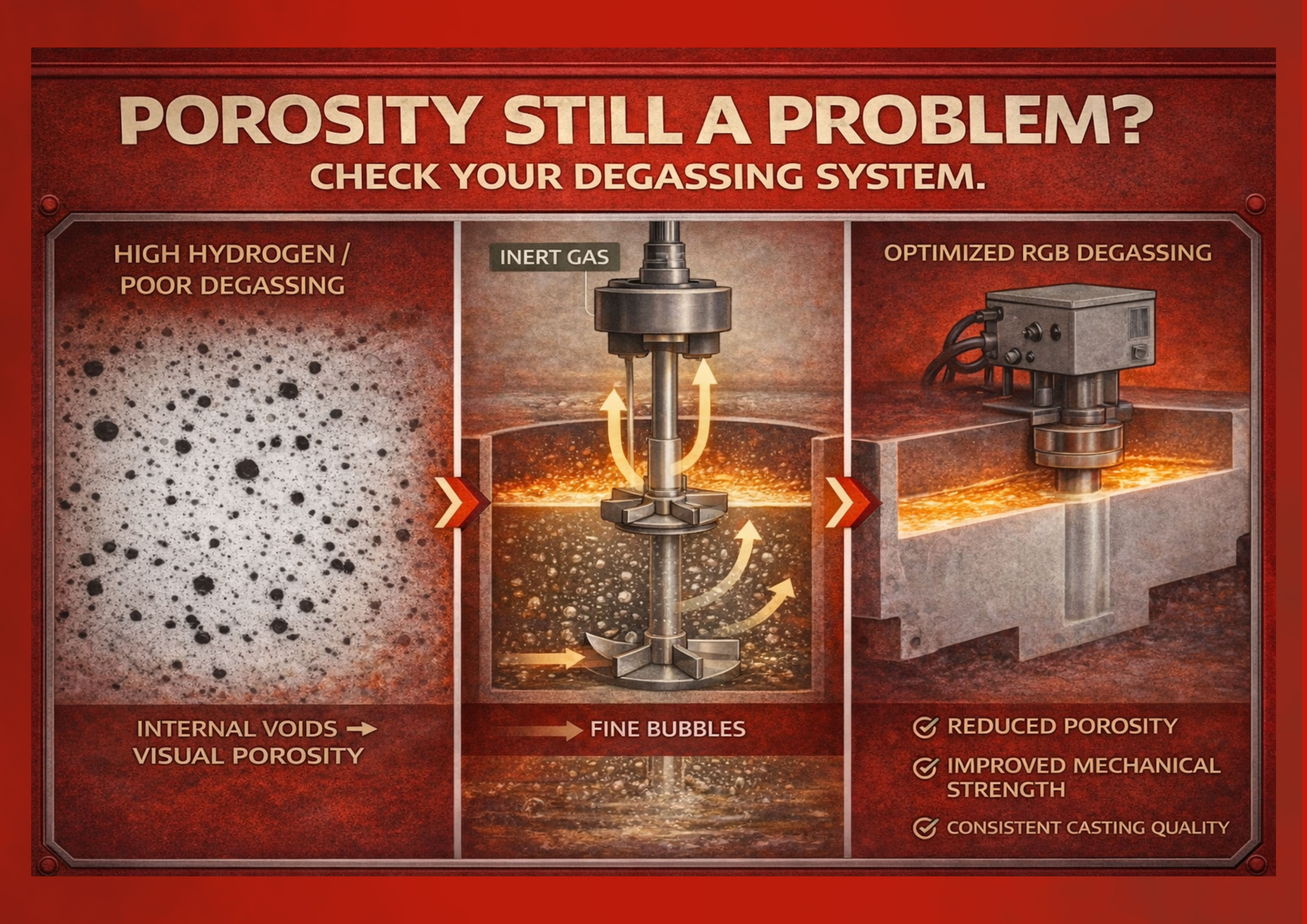

Porosity remains one of the most common and costly defects in aluminum casting. Blisters, pinholes, reduced mechanical strength, and poor surface finish are often traced back to a single root cause: dissolved hydrogen in molten aluminum.

If porosity persists despite good melting and fluxing practices, it may be time to take a closer look at your degassing system and hydrogen removal efficiency.

Why Hydrogen Causes Porosity in Aluminum?

Molten aluminum has a high affinity for hydrogen. During melting and holding, hydrogen is absorbed from moisture in the air, charge materials, fluxes, and furnace atmospheres. While hydrogen dissolves easily in molten aluminum, its solubility drops sharply during solidification.

As the metal cools, excess hydrogen is released and forms gas bubbles that become trapped in the casting, resulting in internal porosity, surface blisters, and reduced material integrity.

The role of degassing and why rotary degassing is more effective

Degassing is the process of removing dissolved hydrogen gas from molten aluminum before casting. This is typically achieved by introducing an inert gas such as nitrogen or argon into the melt. As fine gas bubbles rise through the metal, they capture dissolved hydrogen and carry it to the surface, where it can be safely removed.

Compared to static bubbling or lance-based systems, rotary degassing (RGB) offers superior hydrogen removal through controlled and uniform gas dispersion. In a rotary degassing system:

Why do we need an optimized RGB degassing system?

We provide reliable RGB degassing units, ceramic shafts, and impellers designed to improve hydrogen removal efficiency in aluminum melting and holding operations. Our solutions are suitable for small to medium-scale smelters, holding furnaces and transfer ladles and die-casting and foundry operations requiring consistent quality.

For expert guidance and product recommendations tailored to your operation, contact PT Wilisindomas Indahmakmur.