PT Wilisindomas Indahmakmur recently had the pleasure of hosting one of our trusted principals, Precimeter, for an exclusive training and product update session. This session was not only an investment in product knowledge but also a reinforcement of our commitment to continuous improvement and delivering smarter solutions to the aluminum die casting industry.

Empowering Our Engineers

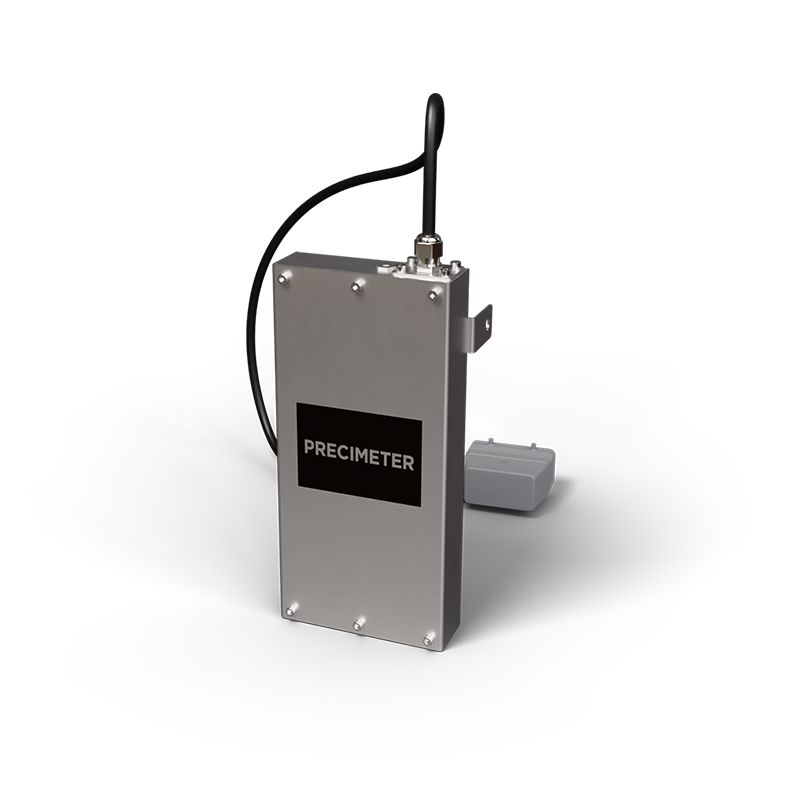

The agenda kicked off with in-depth training on Precimeter’s molten metal control solutions, including inductive sensors and laser-based systems. These technologies are key for improving precision in metal level control, temperature management, and overall process automation in casting.

Through this training, our engineers deepened their understanding of:

- The ProLAD system – Precimeter’s laser camera sensor that provides real-time, high-accuracy molten metal level control.

- The PLPR sensor – an inductive solution optimized for highly conductive metals such as aluminum.

- Latest product enhancements and installation techniques.

Laser Camera Sensor Applications

As a core product from Precimeter, the laser camera sensor is widely used in billet casting, slab casting, and is becoming increasingly important in the extrusion process. Its precision and non-contact technology allow for stable, consistent monitoring—leading to improved casting quality and reduced material waste.

On-Site Experience with Our Clients

After the classroom sessions, our team joined Precimeter on client visits to observe live molten metal processes across several production plants. These on-site observations allowed our engineers to see real-world challenges and how Precimeter’s smart sensors contribute to better control and reduced waste.

One key focus was the High Pressure Die Casting (HPDC) process. With its speed and complexity, HPDC presents many challenges—especially in molten metal transfer and level control. By integrating smart sensors like ProLAD and PLPR, casthouses and plants can be upgraded into more efficient, cost-effective, and sustainable operations.

Why This Matters

At PT Wilisindomas Indahmakmur, we believe in equipping our team with the latest knowledge and tools to support our customers better. This training and collaborative effort with Precimeter ensure that we remain a trusted technical partner in Indonesia’s growing aluminum die casting sector.

If you’re exploring automation and control solutions for molten metal handling, get in touch with our team. We’re ready to help you transform your operations with high-performing sensor technologies.

👉 Contact us today to discuss your HPDC or casthouse challenges.

📞 www.wilisindomas.com